Dynamic Engineering specialises in high capacity maintenance stand design. These stands are designed using the principles of the Australian Standards (AS2538) and experience gained in this field over a period of 10 years. From a design point of view, we use Finite Element Analysis, making it possible to ensure that the stand has adequate capacity to resist deformation and buckling. In addition, we also take into account stability and strength as well as ease of handling. Finally, all designs are engineer certified – meaning that a Chartered Engineer, Registered with Engineers Australia, has signed off on the design.

Below are some examples of our many designs. First up are maintenance stands used for mobile equipment:

Mobile Equipment Maintenance Stands

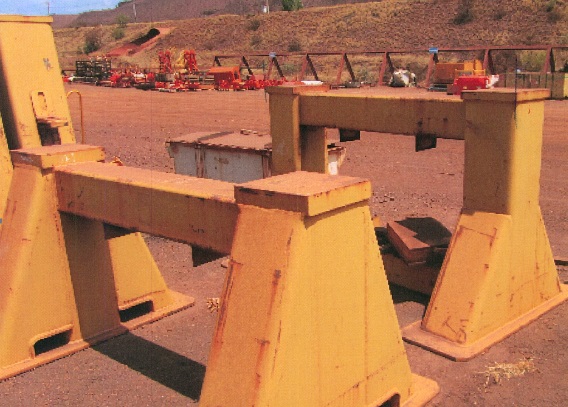

At Dynamic Engineering Consultants we are always adding to our design inventory and as such we have developed maintenance stands for several existing machines. For example, the stands shown below is for a Komatsu WA1200 front end loader. These stands have a 200T capacity (100T each side).

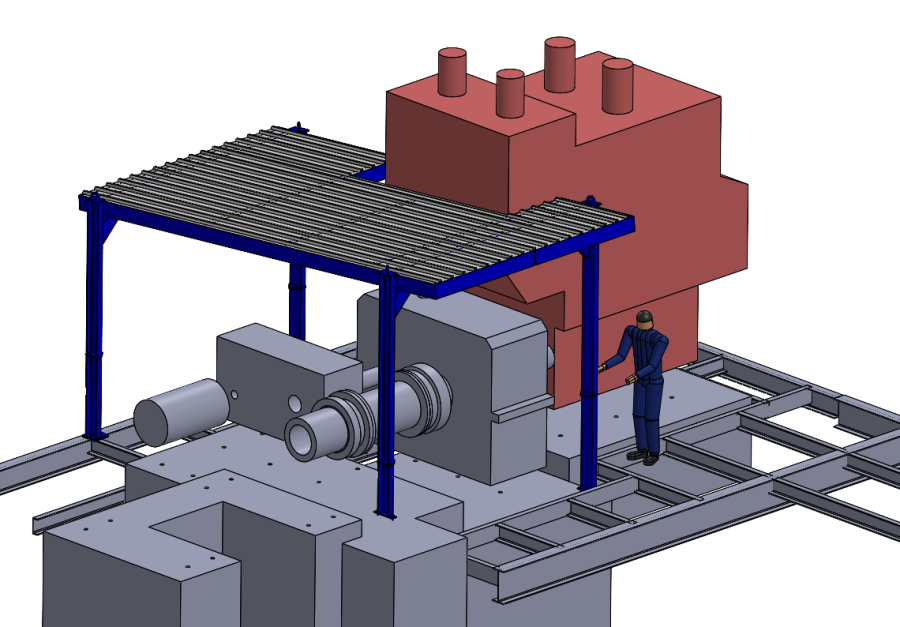

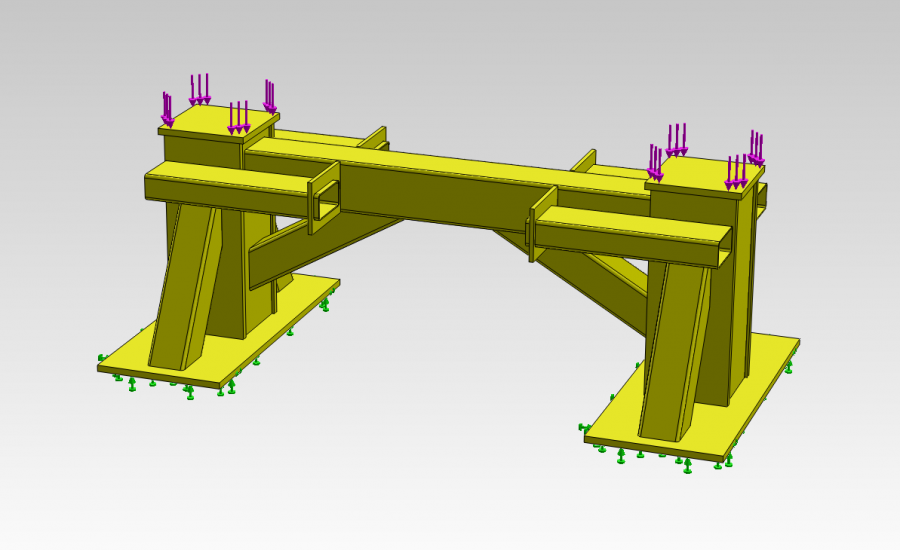

Below the design process is shown in more detail. Firstly we create a 3D CAD model, showing the maintenance stand with forklift sleeves on top. These forklift sleeves make for easy placement of these stands.

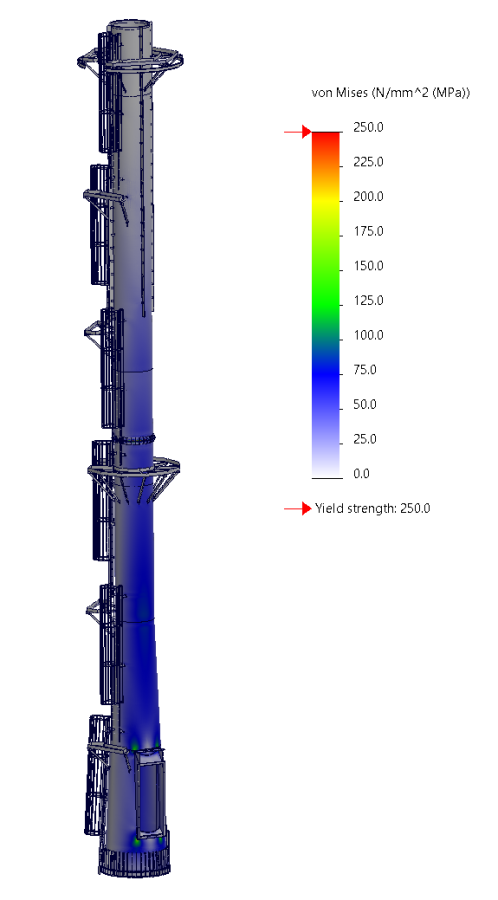

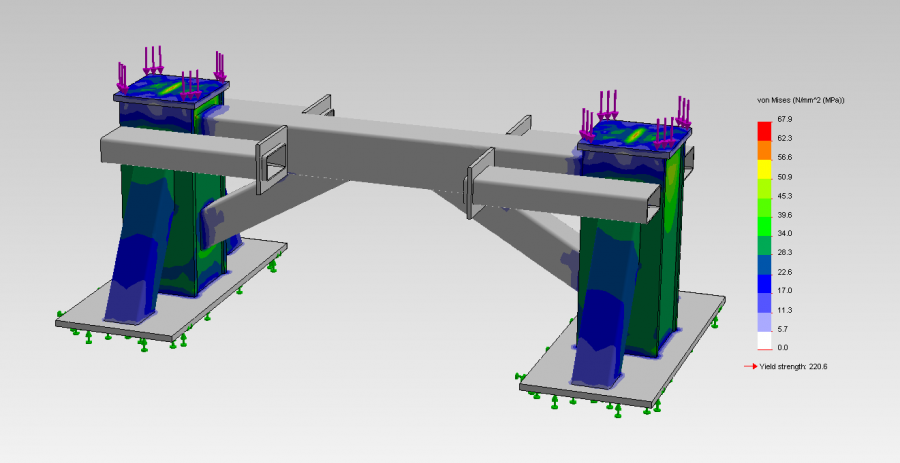

Secondly FEA is used to analyse the model to find the resultant stresses. The stress plot is shown below:

Finally, after finishing the design, shop drawings are produced and the stands are fabricated. Below are examples of these stands in three different sizes.

Stands with Wheels

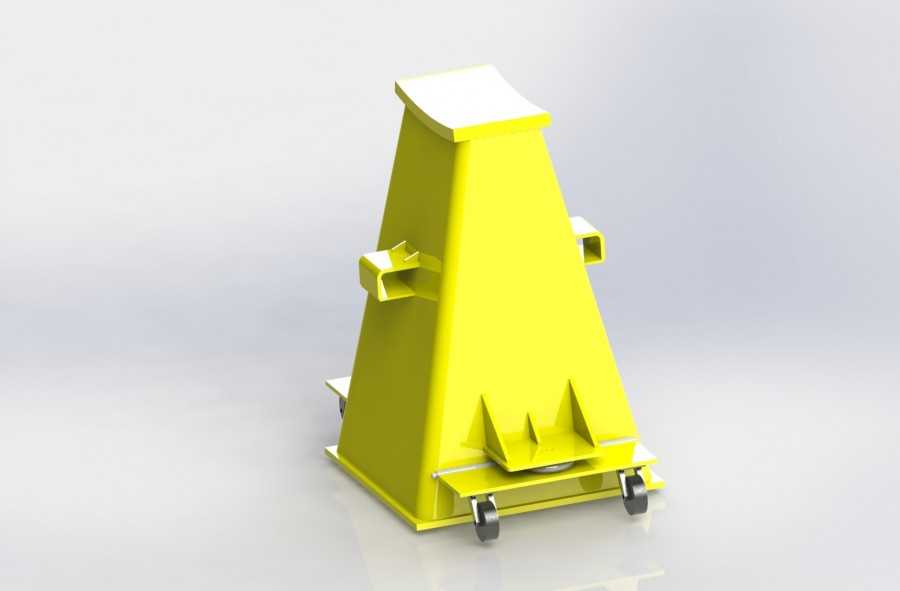

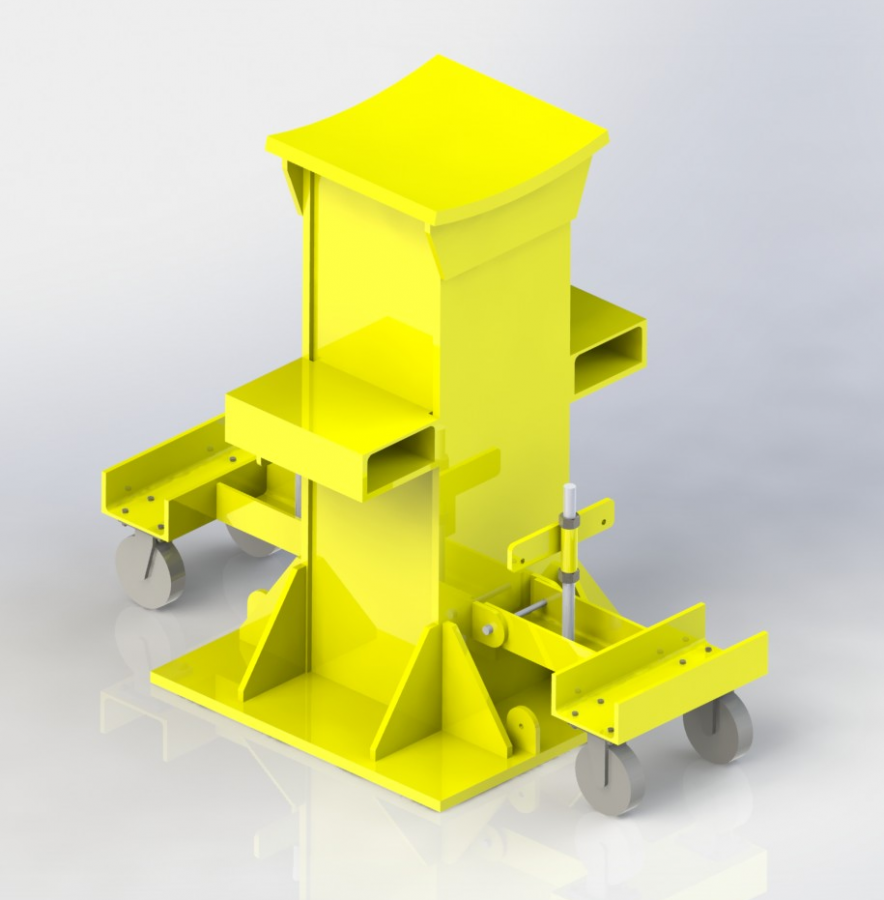

During maintenance workers might need to move equipment around the workshop. To facilitate this. we added heavy duty wheels to the stands. Below are examples of these stands with wheels:

115T stand with pneumatically actuated wheels

Curved top stand with spring loaded wheels

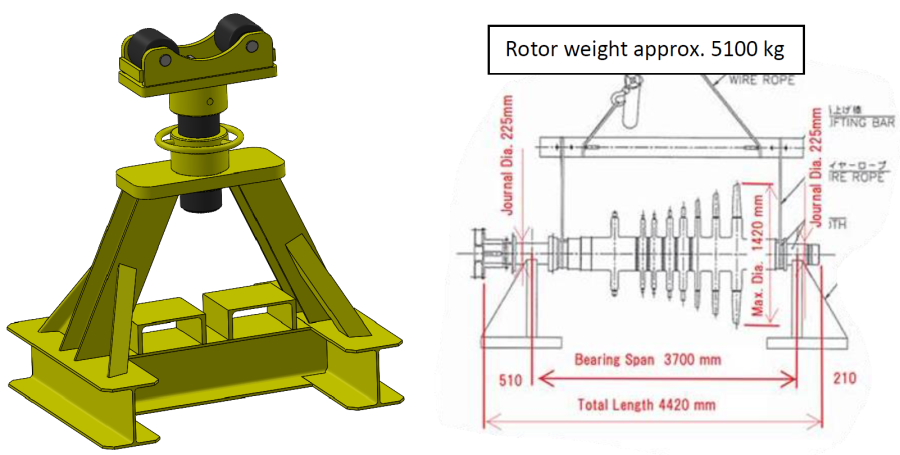

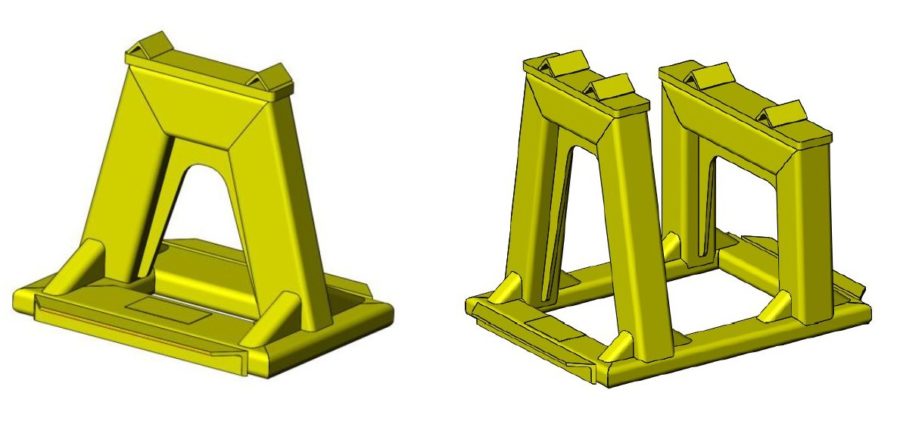

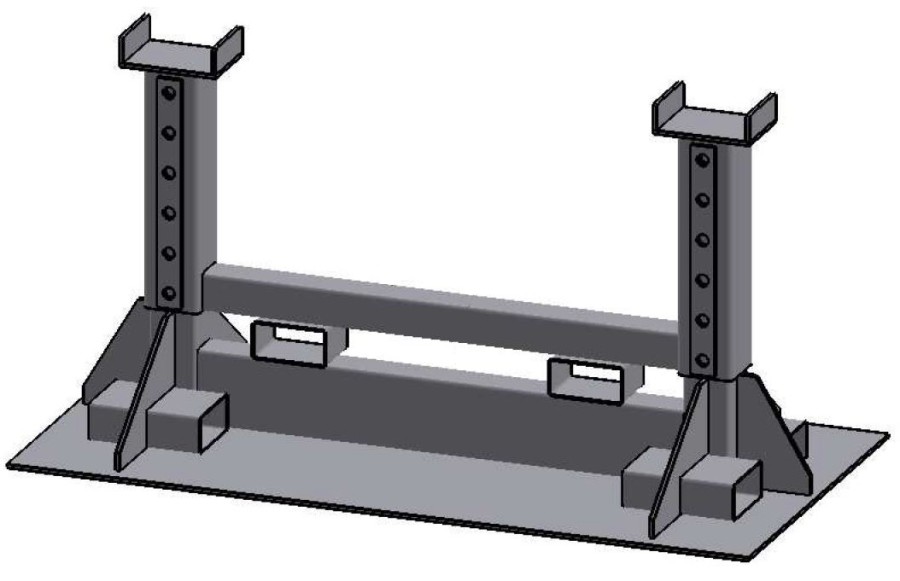

Rotor Shaft Stands

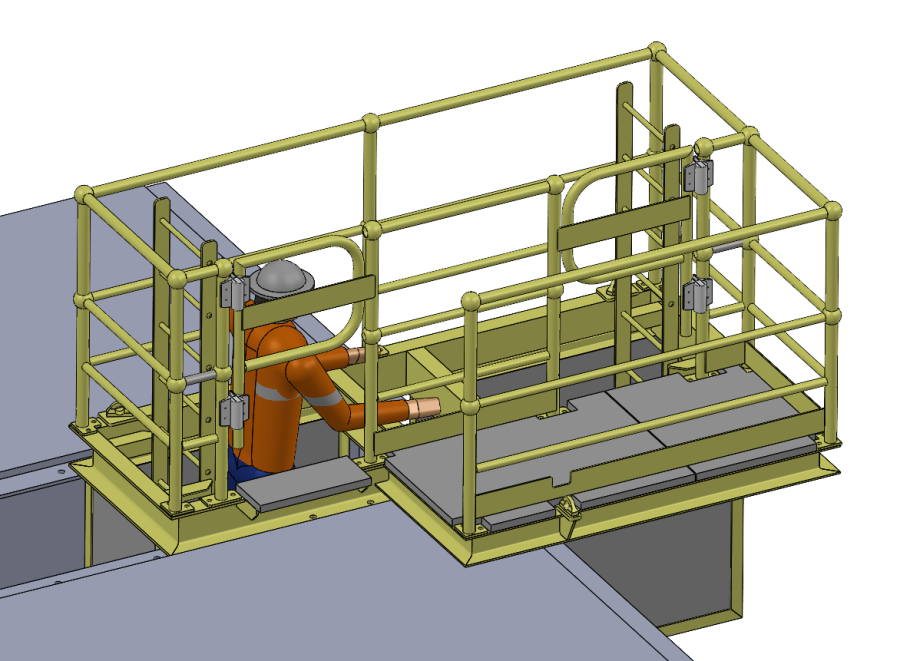

When maintenance personnel needed to work on mill rotor shafts, they required custom made shaft stands, which can withstand the weight of the shafts. Below are examples of these stands, first the 3D model stands are shown, followed by the fabricated stands.

Rotor shaft stands, single and double stand

Mill rotor shafts

Our client needed these stands urgently and Dynamic Engineering was able to design these stands in a timely manner so that maintenance could run on schedule.

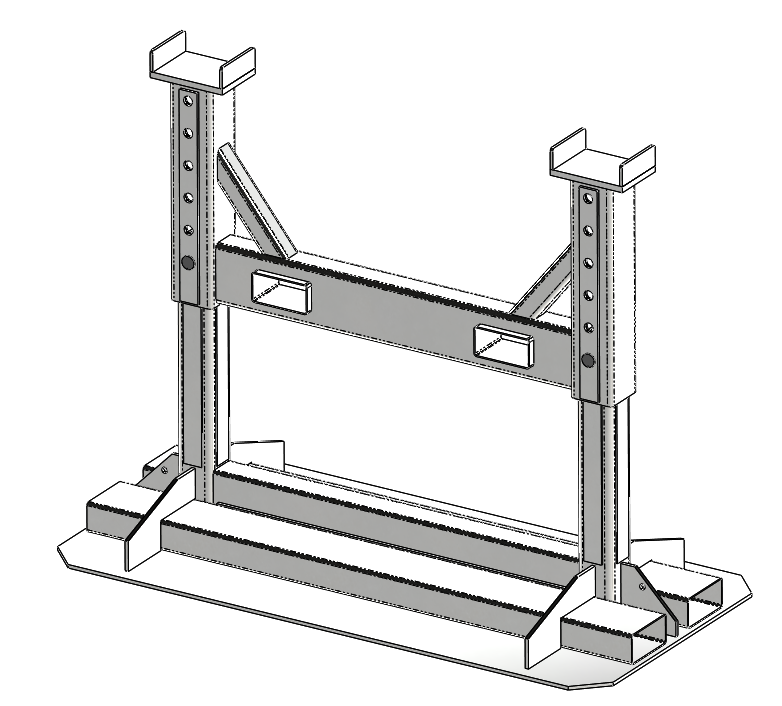

Client’s Custom Design Stands

Many of our clients are happy to fabricate their own equipment, but need help converting their concept ideas into a design that complies with the Australian Standards. Dynamic Engineering works with our client, fine tuning the maintenance stand design until it complies, and can then assist with generating accurate fabrication drawings.

In one such an example, our client wanted to analyse a drill mast stand with a WLL = 25T. Below is the concept along with the final design.

Client’s concept

Final Design

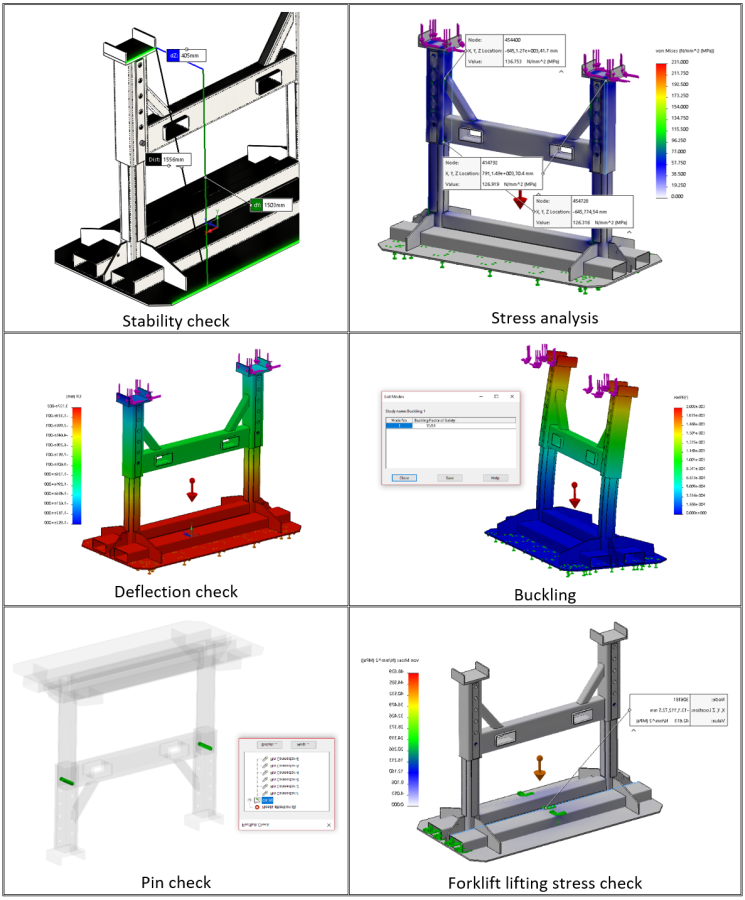

The concept had to undergo several modifications to comply with the stress, deflection, stability, buckling requirements. In addition. the pins were checked to see if they were strong enough and finally the stand was checked while being lifted with the forklift.

Finite Element Analysis

If you have similar requirements for maintenance stands, please contact us to see how we can assist you.