From time to time a specific job requires a particular tool that is not available off the shelf. In these cases, in the interest of safety, the tool may have to be certified for certain loads. Dynamic Engineering can assist our clients by certifying tool designs for certain applications and loads. This maintenance tools design certification is always done against a specific Australian Standard and requires the following:

1) Fixed design (Generally the design is fixed in terms of an accurate drawing that states the processes (welding etc) as well as the material standard and grades.

2) Fixed or specified loads (Torque, Force etc).

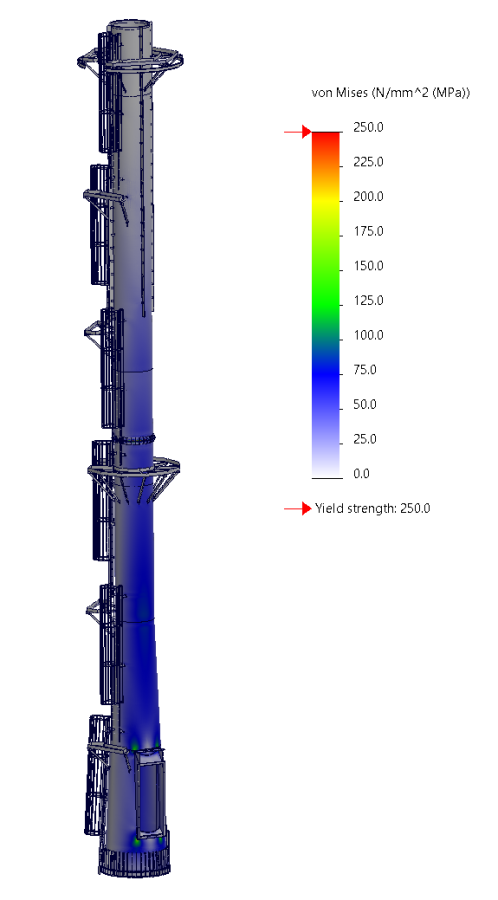

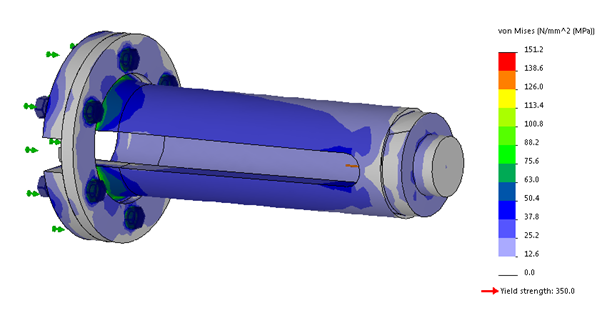

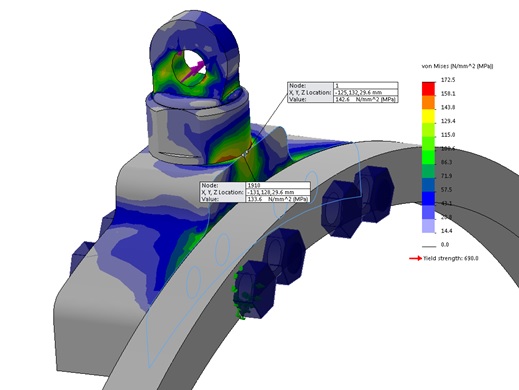

Firstly, we model and analyse the tool with Finite Element Analysis. Afterwards the loads are applied and the stresses and deflections are determined and compared with the requirements of the applicable Australian Standard. Working with our client, we tweak the design until the stresses are lower than what is permissible according to the Australian Standards. Finally, we generate a report for certification purposes (and drawings if required).

Below are some examples of tools:

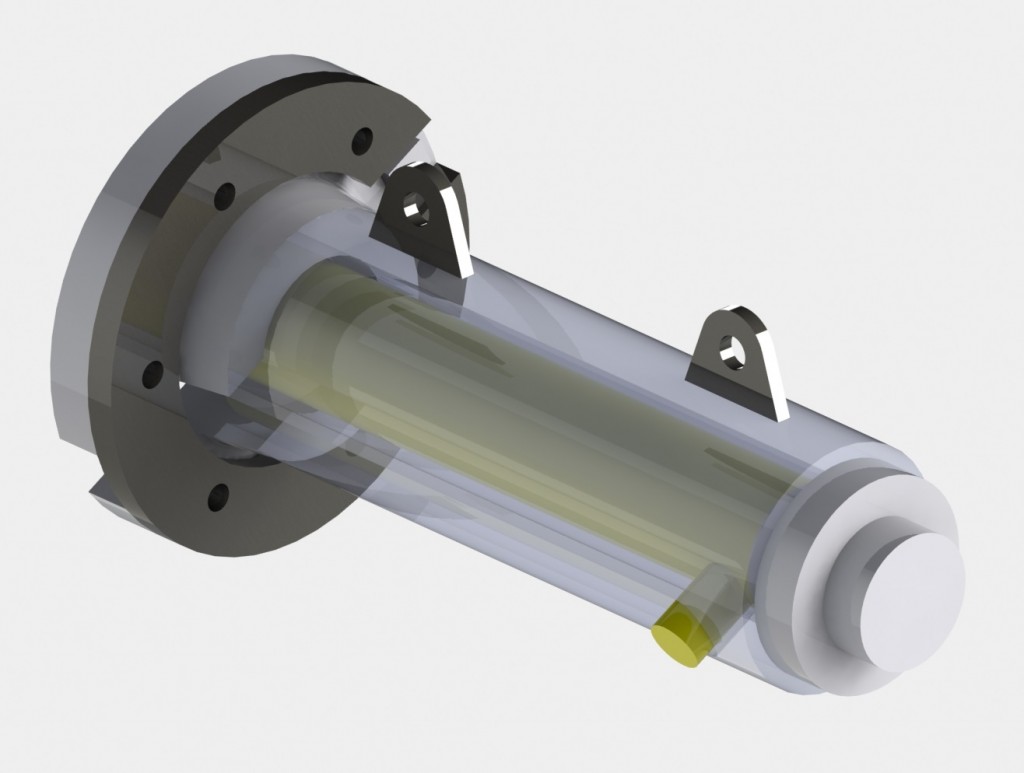

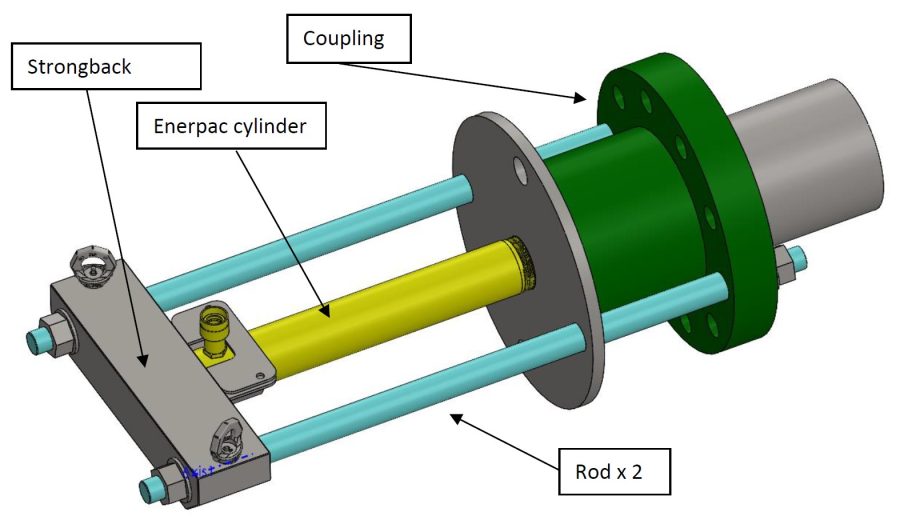

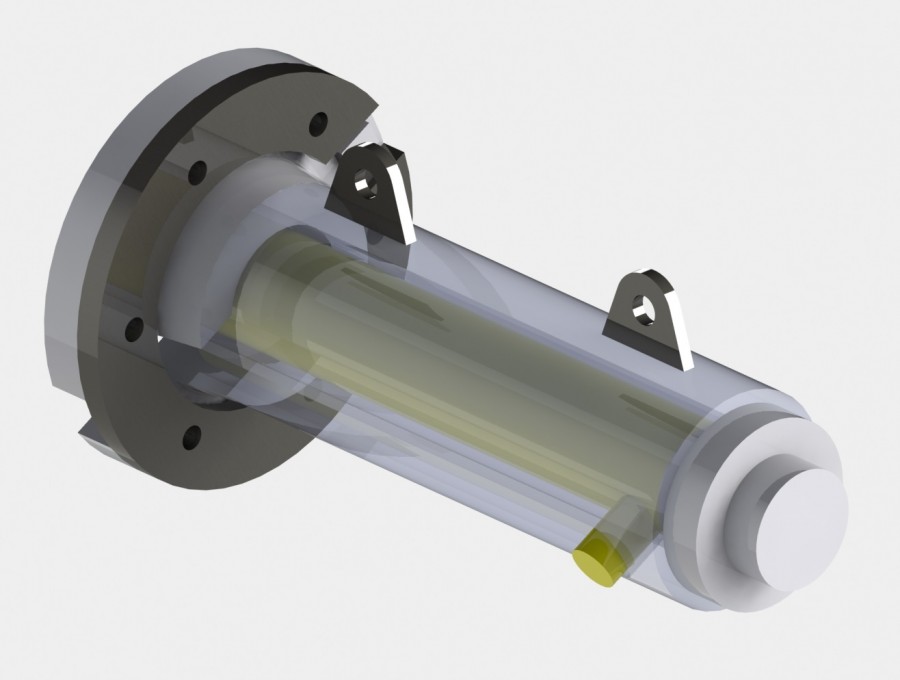

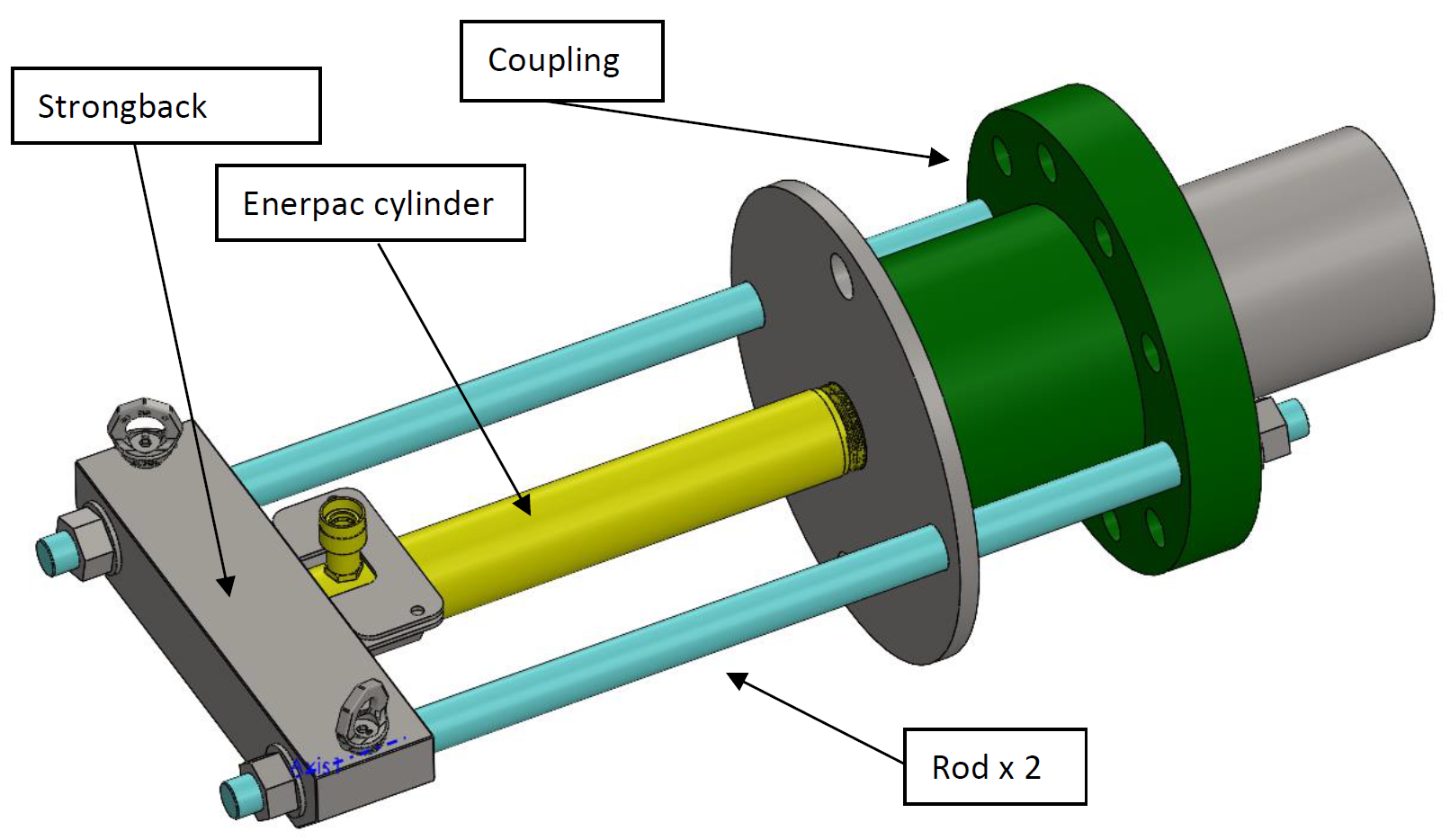

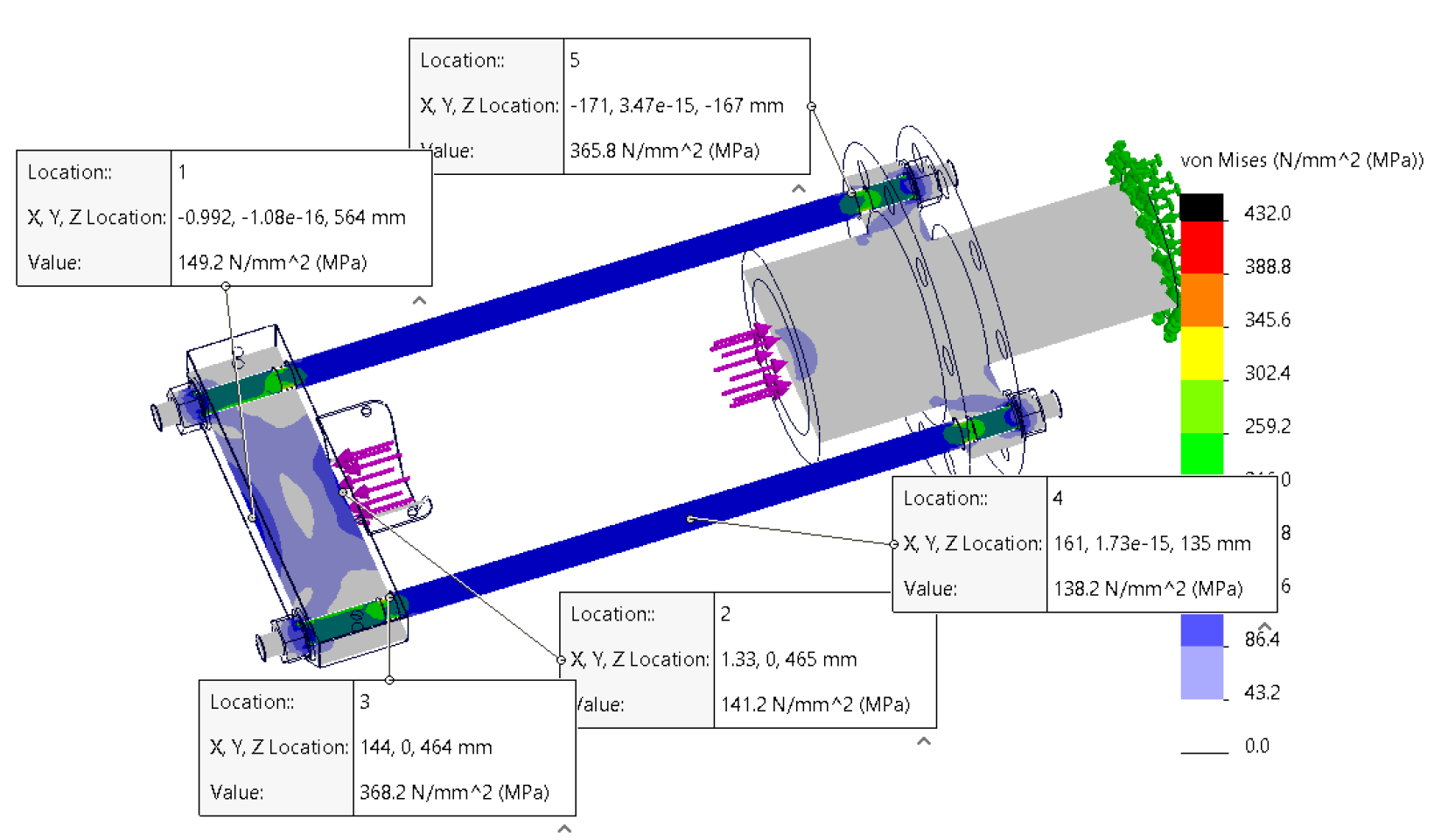

Hydraulic Push Puller

The picture below shows a 3D model of Hydraulic Push Puller:

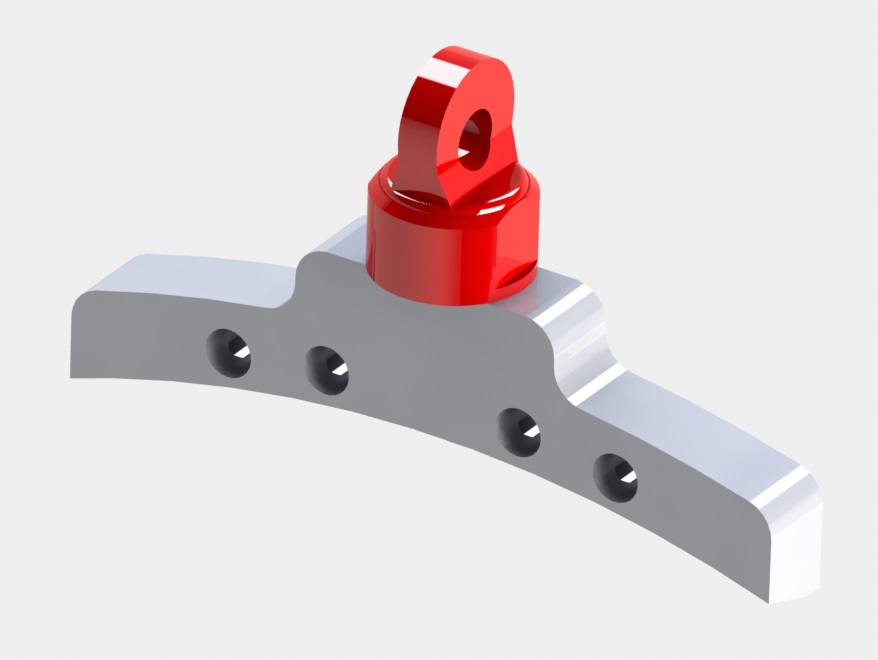

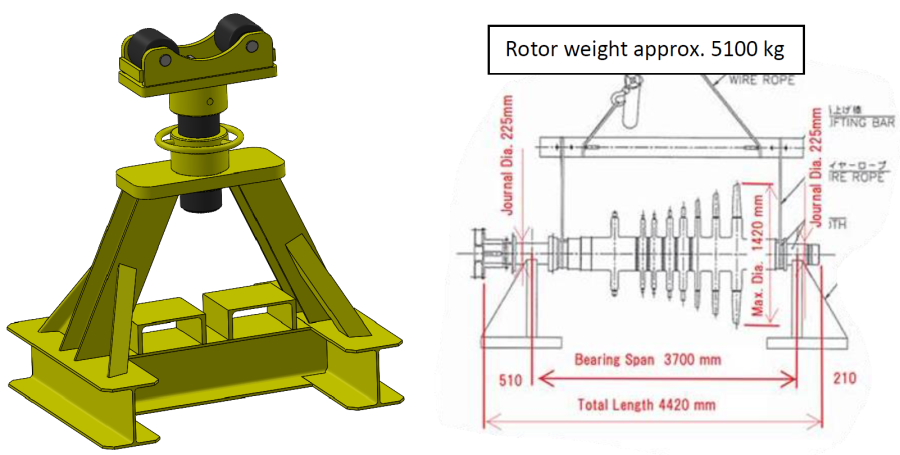

Lifting bracket

The picture below shows a 3D model of a lifting bracket

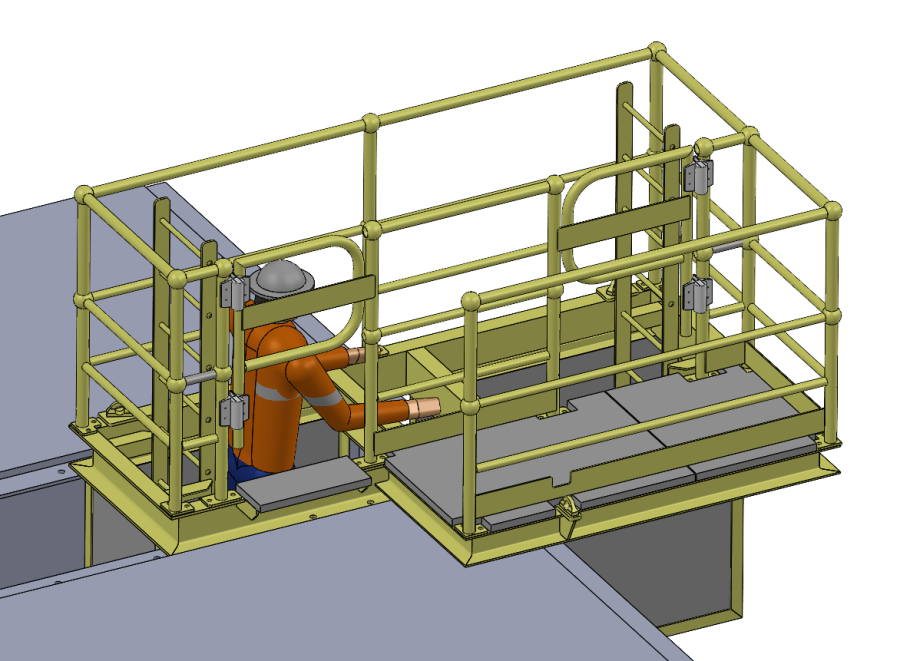

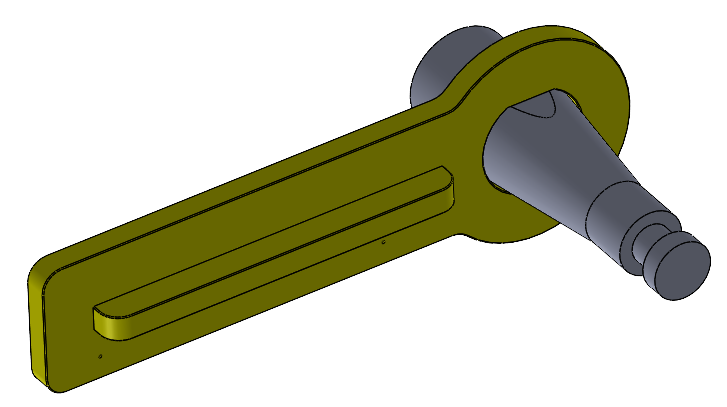

Locking spanner

Strongback

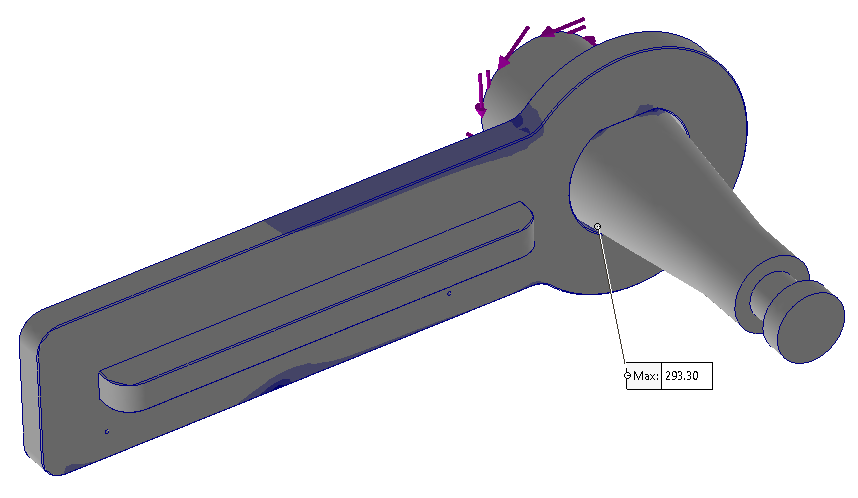

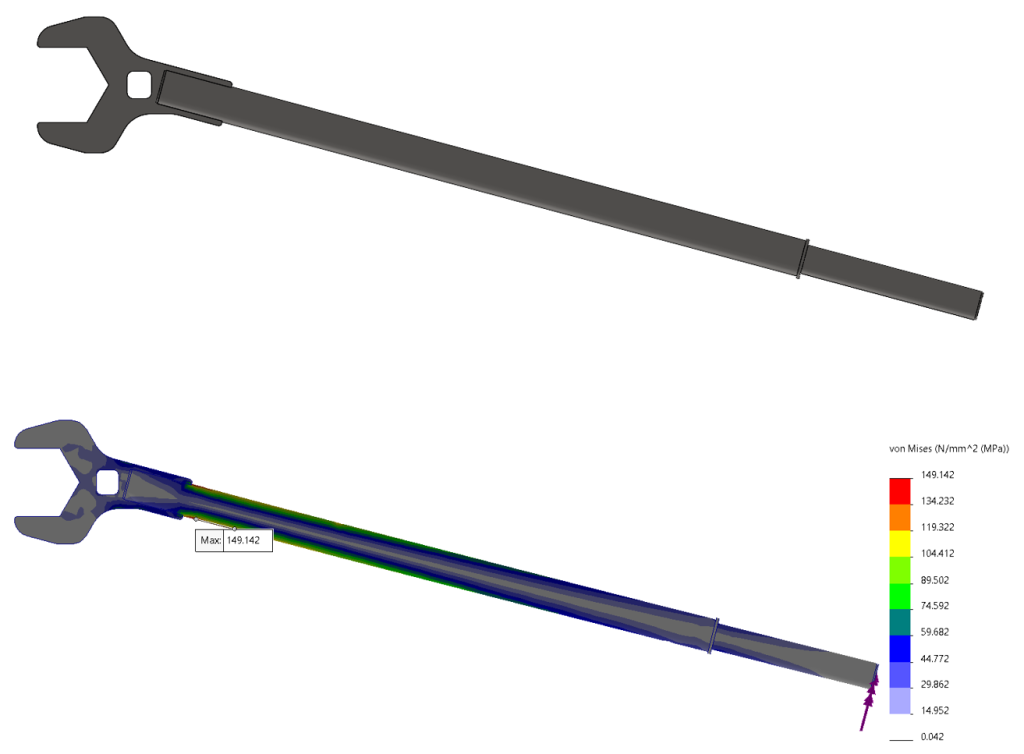

Spanner

Below is an example of a spanner that had to be as light as possible, whilst still be able be able to resist the forces applied by a worker.

The above examples are just some of hundreds of design certification of maintenance tools Dynamic Engineering Consultants have completed. Therefore, if you have a specific maintenance tool that you would like to design or if you have existing tools that needs to be certified, please contact us.