A dedicated maintenance platform can provide easy and safe access to equipment for maintenance purposes. As a result, this could reduce downtime or shut down costs. After all, there are several different types of custom-made platforms to suit a range of requirements. For instance, Maintenance Platforms, which are permanently located around large critical equipment, can provide ongoing access to equipment of rotatable spares. Likewise, for an application with limited access, Access Platforms could be the answer to reach restricted work areas. Or, if you only need a temporary platform which can be moved into and out of position, a Lightweight, Movable Platform may suit your needs. And lastly, if you are after a more robust mobile platform, please look at Steel Portable Platforms. We can help with the design and drafting of a platform that will suit your specific needs. In addition, this bespoke platform design will conform to Australian Standards and will be certified to safely withstand the applied loads.

Maintenance Platforms

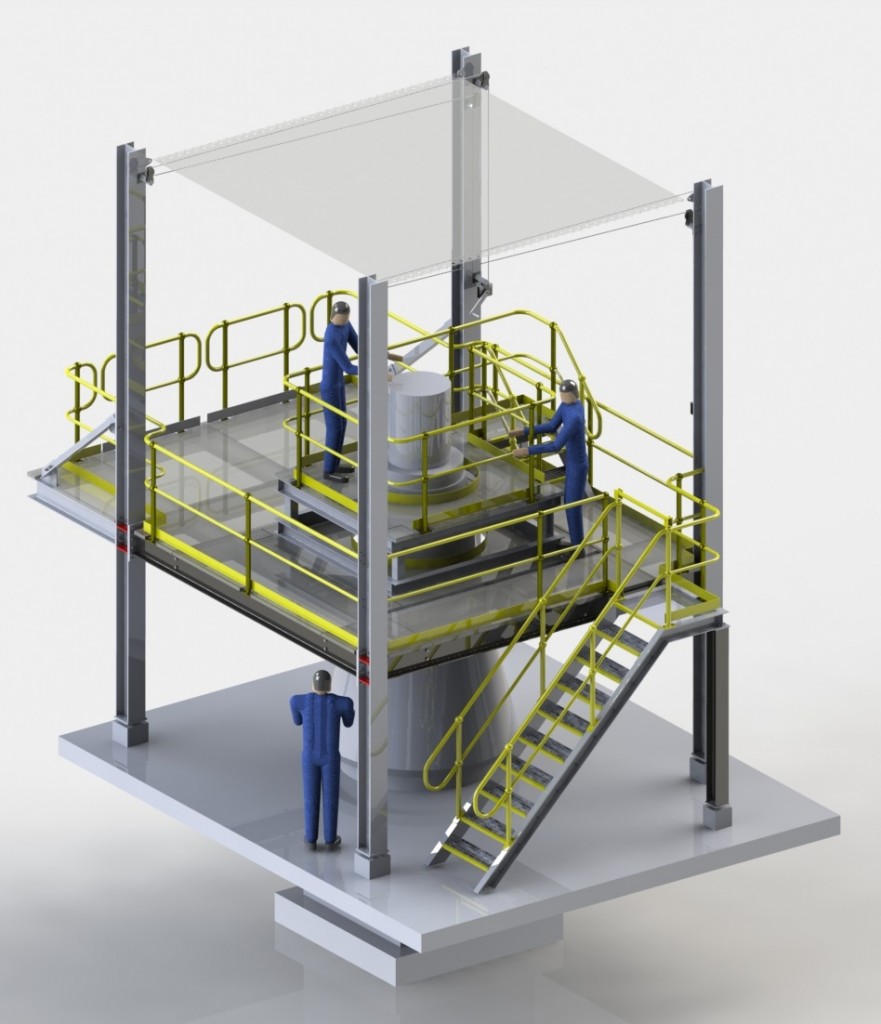

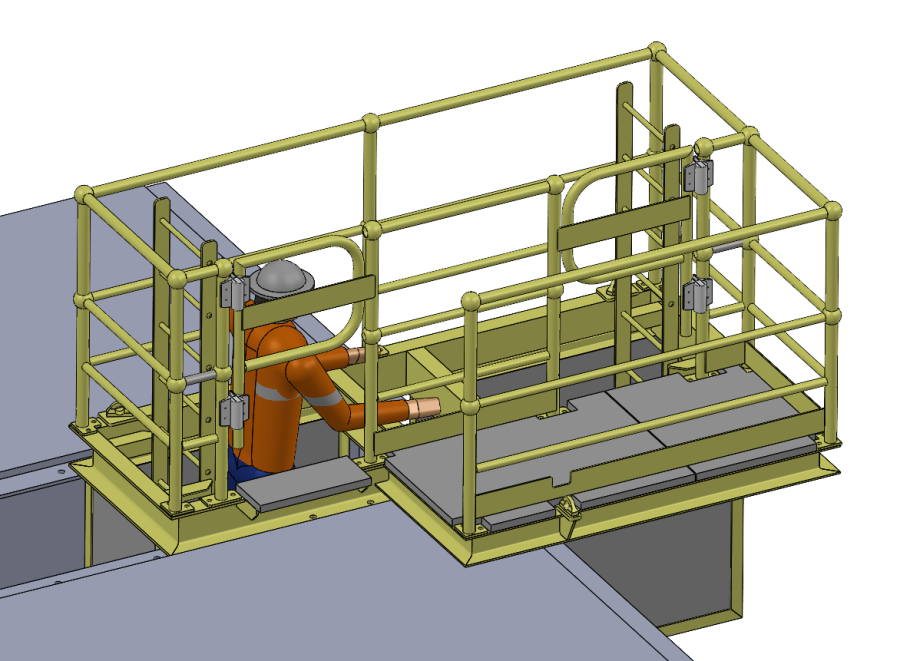

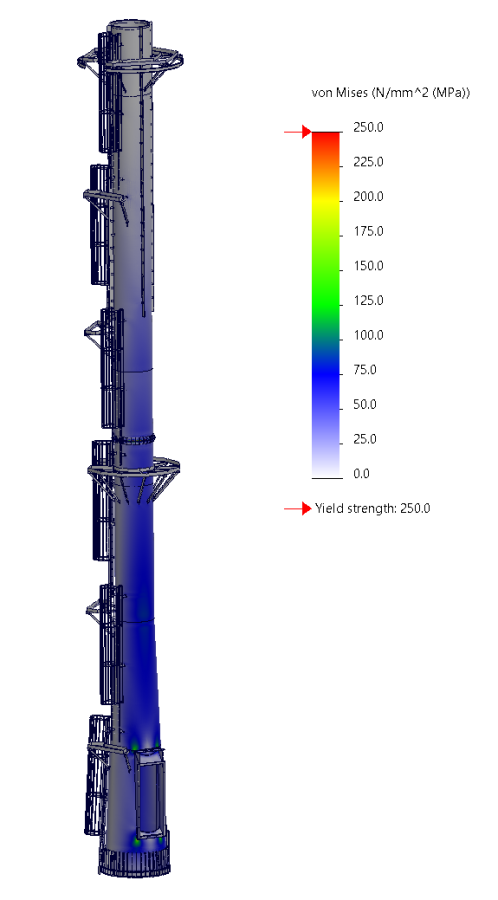

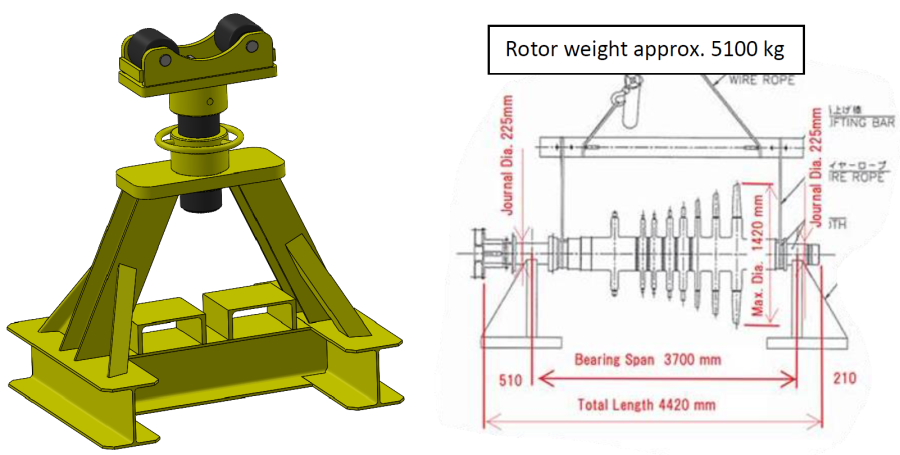

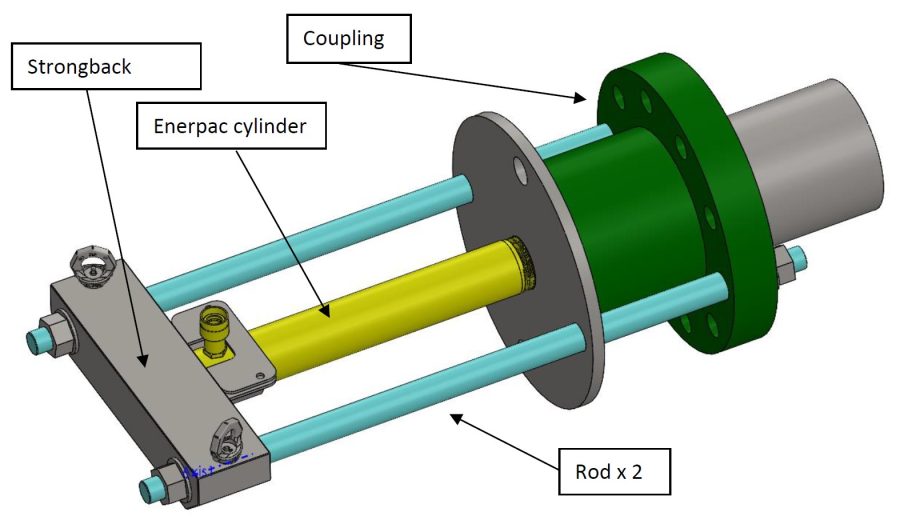

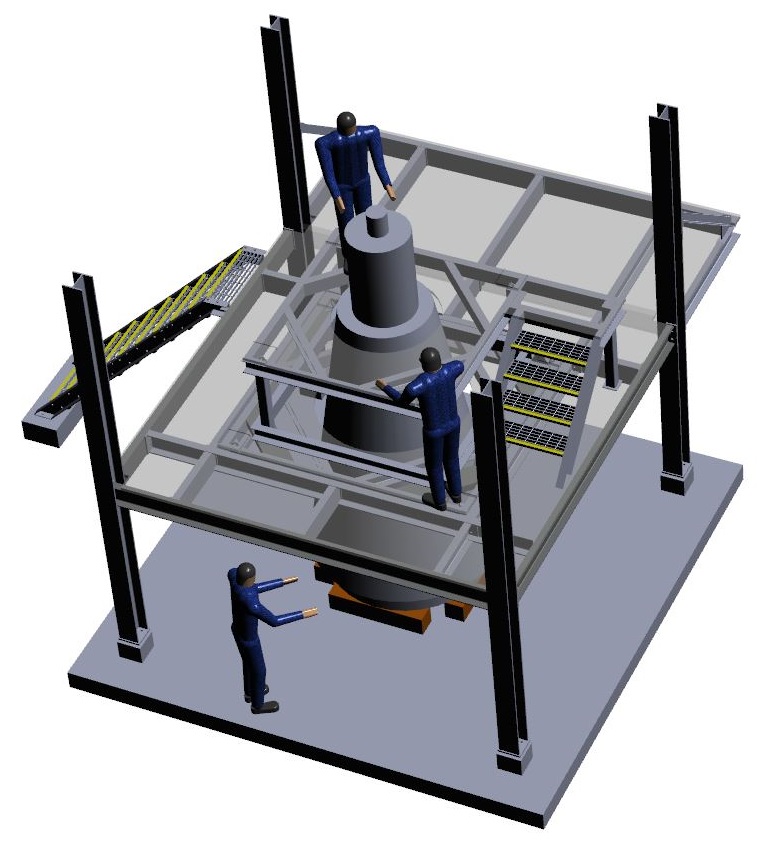

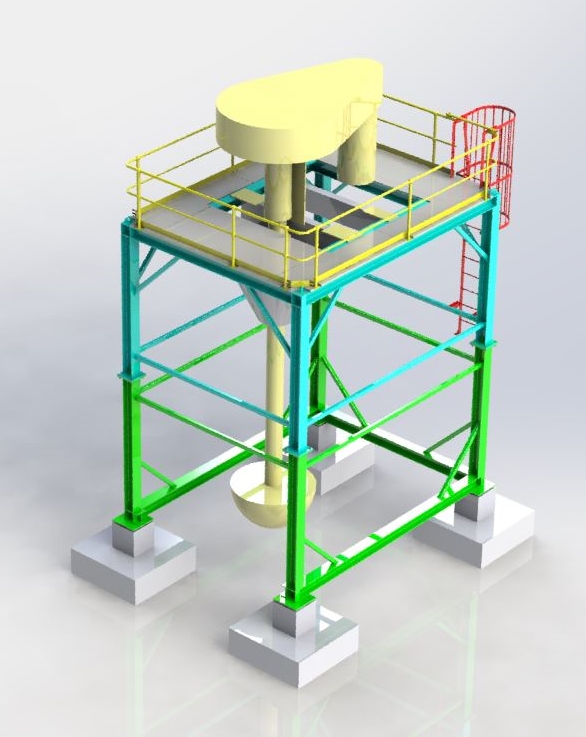

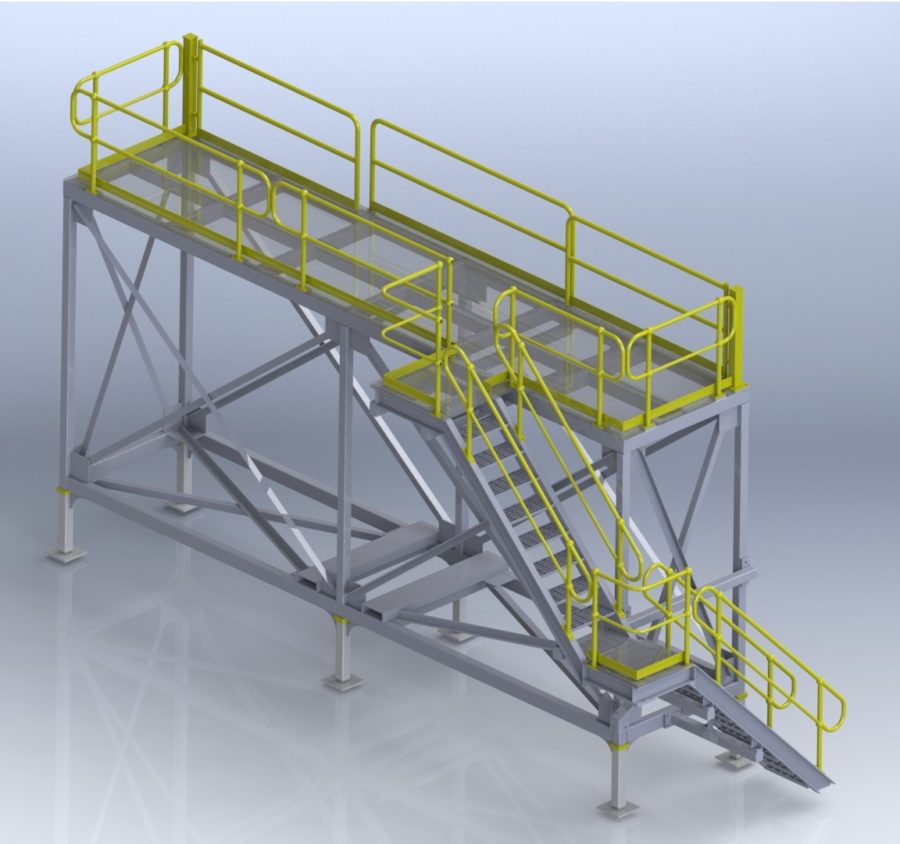

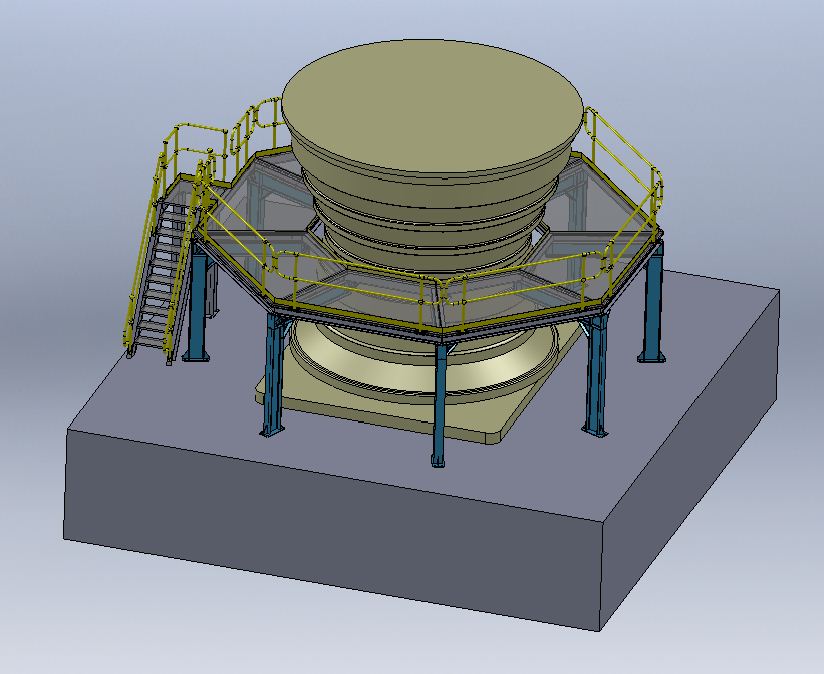

Maintenance platforms located next to equipment can provide significant savings in terms of maintenance downtime costs. This is especially true for large equipment like Gyratory Crusher main shaft assemblies and Flotation Mixer. Furthermore, these platforms can be custom made for most equipment and installations. As an example, below is a couple of examples of large maintenance platforms Dynamic Engineering Consultants designed.

Gyratory crusher maintenance platform:

Flotation cell rotor maintenance platform:

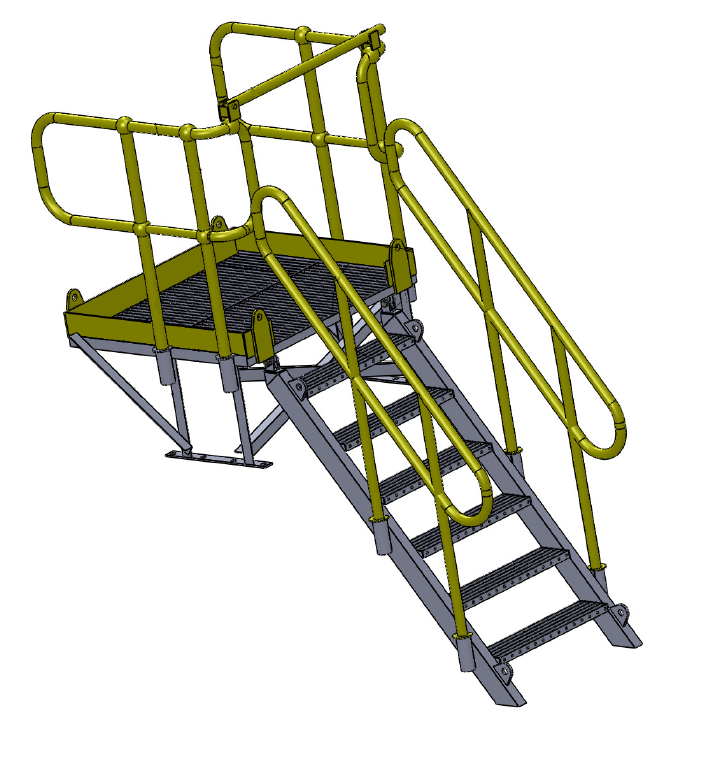

Access Platforms

Occasionally, mining operations require tailor made engineering solutions due to space and operational constraints. With this in mind, we provided designs for such an access platform extension. For this reason, the underground platform is suspended from the “back” of the portal and is furthermore connected to an existing platform. As an illustration, refer below for some pictures of this platform design.

Lightweight, Movable Platforms

When performing maintenance, lightweight platforms can easily provide access to equipment. With this purpose in mind, we can design these custom maintenance platforms to suit your specific needs. For example, one of our projects was to design and analyse a lightweight ball mill inspection platform. The first picture below shows the 3D CAD model. This is followed by the completed maintenance platform used during the shutdown:

Steel Portable Platform

Dynamic Engineering has completed several steel portable platform designs, which are used for inspections. For example, these platforms are used in the mining industry to inspect excavator buckets, truck trays etc. For easy placement, a forklift first moves the platforms into position. Then they are height adjusted and levelled by means of adjustable jacks.

Specialised Platforms

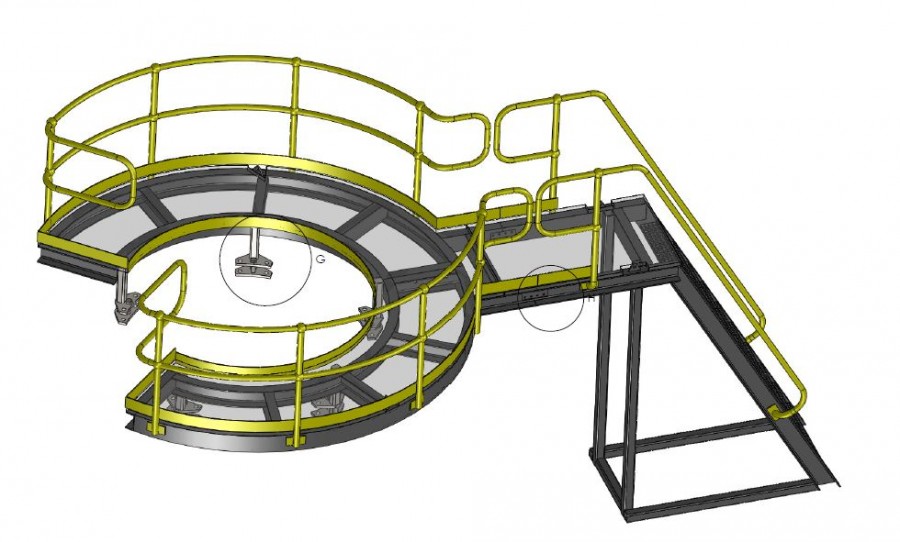

Below are some more examples of access platforms:

The above is just a small example of all the platforms we’ve designed throughout the years. We work with our clients to find the best solution. Contact us today to see how we can help you. Above all, we bring together proven expertise in engineering analysis and best practice in its implementation.