Dynamic Engineering has designed and built several vertical and horizontal plate racks according to our client’s requirements. For example, these racks are available in either welded or bolted configurations, making the design very flexible. In addition, the plate racks are also equipped with lifting lugs for easy loading and unloading for transport purposes. Moreover, we design these racks to Australian Standards AS3390.

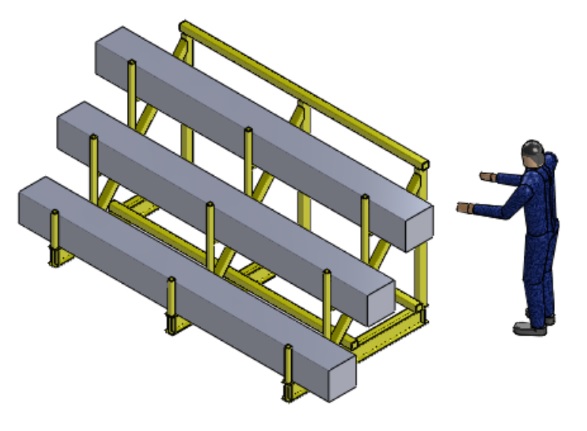

The photo below shows an example of a welded horizontal plate rack:

This rack has a 10T capacity, but designs can be tailored to the client’s needs.

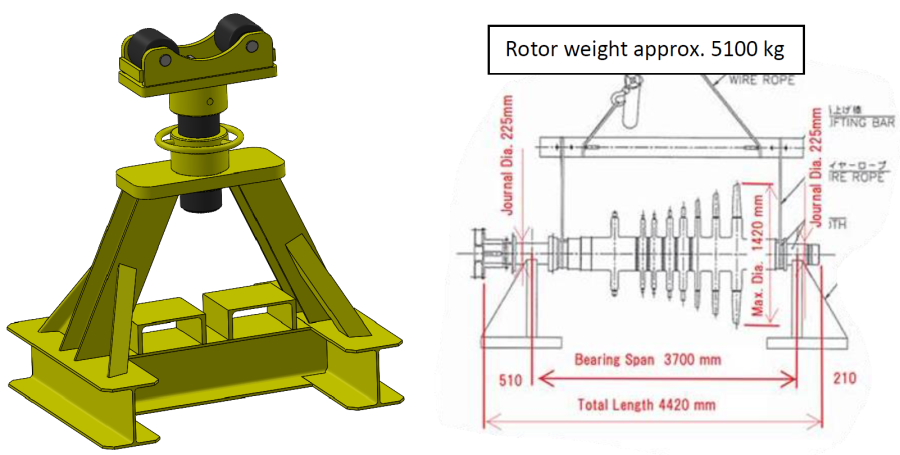

One of our clients required a rack to store square bundles of rods. However, they had limited space and needed as large a storage space as possible. In addition, they still needed enough space for a forklift to place the rods onto the shelves. The picture below shows the 3D model of the eventual design:

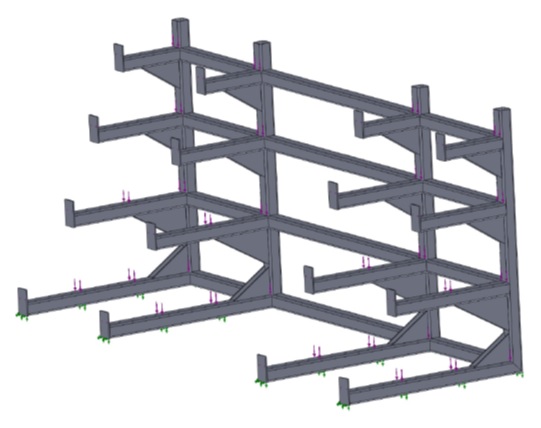

Typical Design Analysis

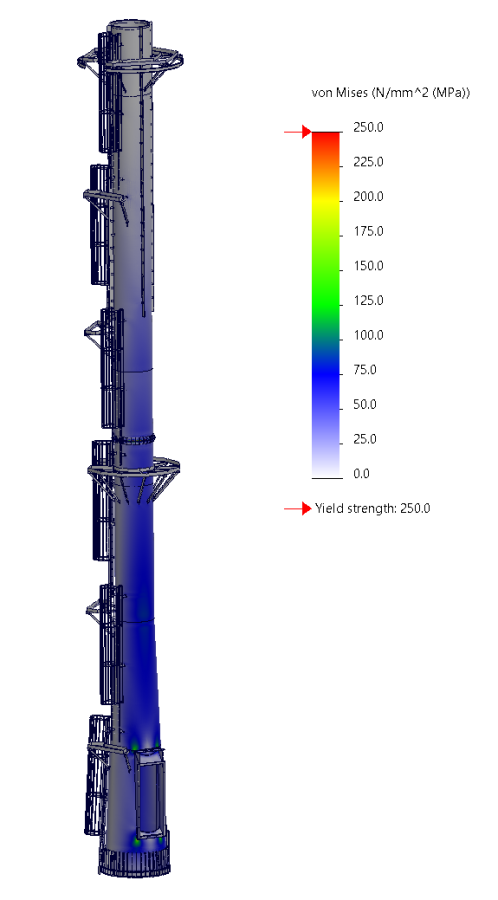

A typical design analysis consists of three parts. The first part is to convert the client’s design into a 3D model, see below:

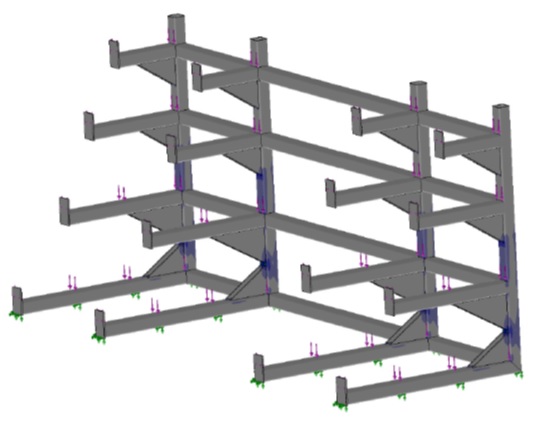

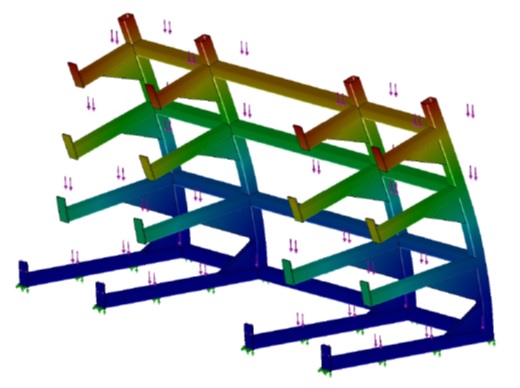

Secondly, we add the various loads and constraints to the model and with Finite Element Analysis determine the stresses and deflection of the model:

The above deflection is exaggerated for easy visual reference.

In the event that the analysis shows that the design is not complient with the Standards, we, in conjunction with our client, modify the design until it complies. Lastly Dynamic Engineering issues a report certifying the design along with shop drawings, if required by the client.

Do you have specific storage needs? Then contact us to discuss your requirements for a plate rack. We will work together with you to find the right storage solution for your workshop.