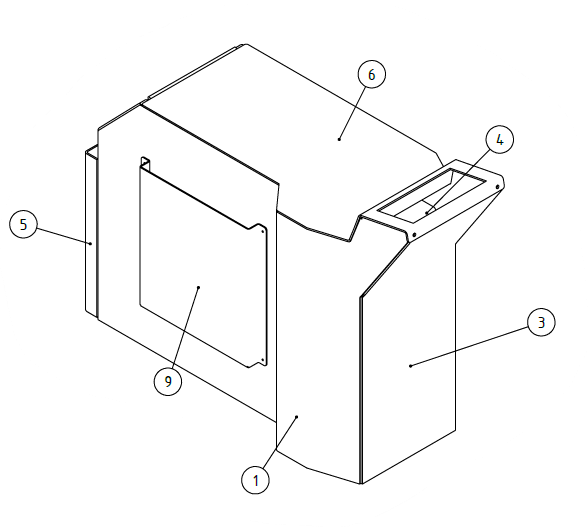

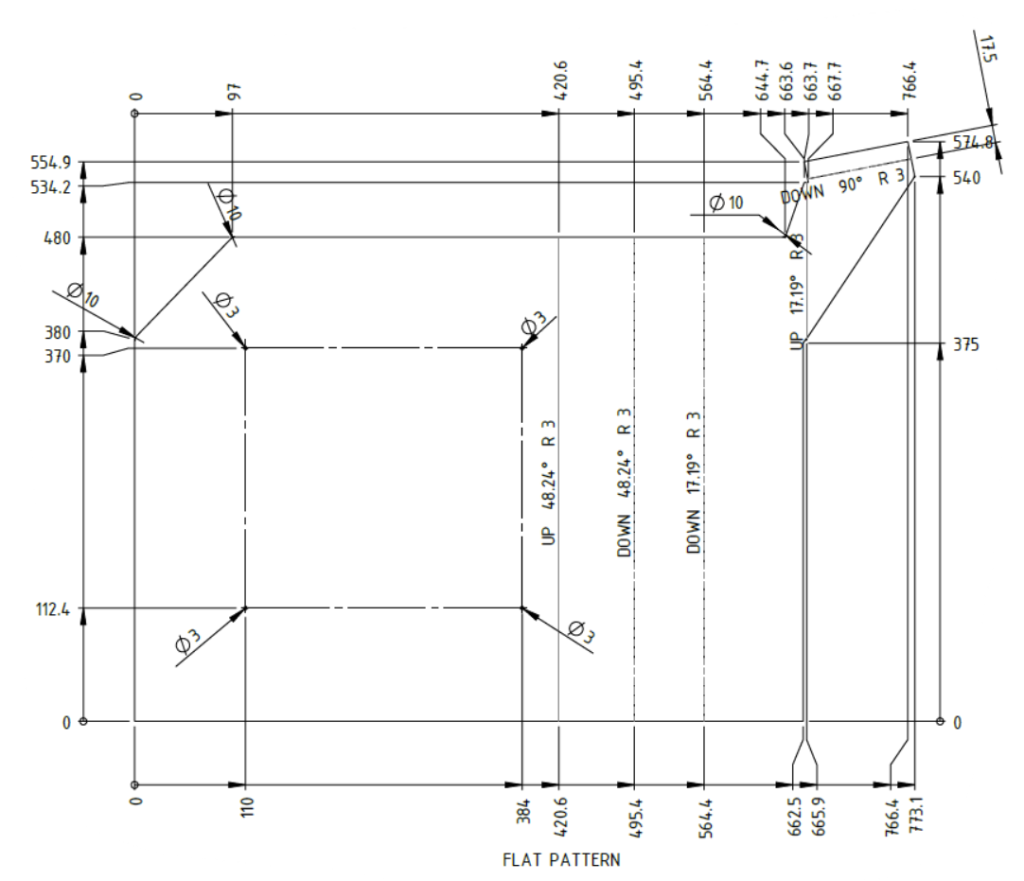

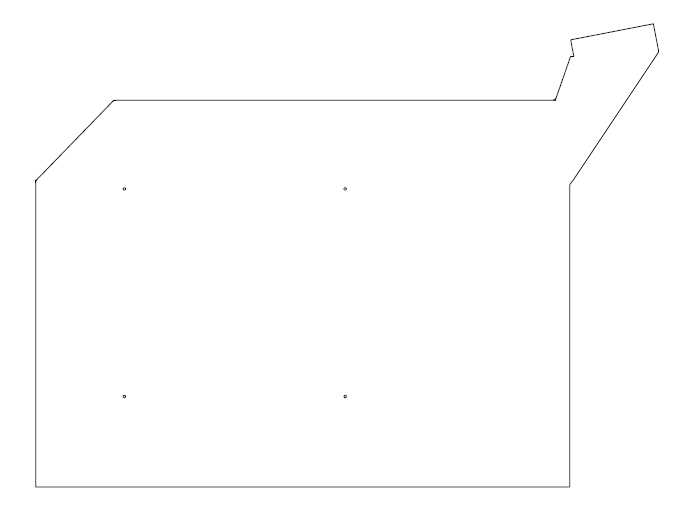

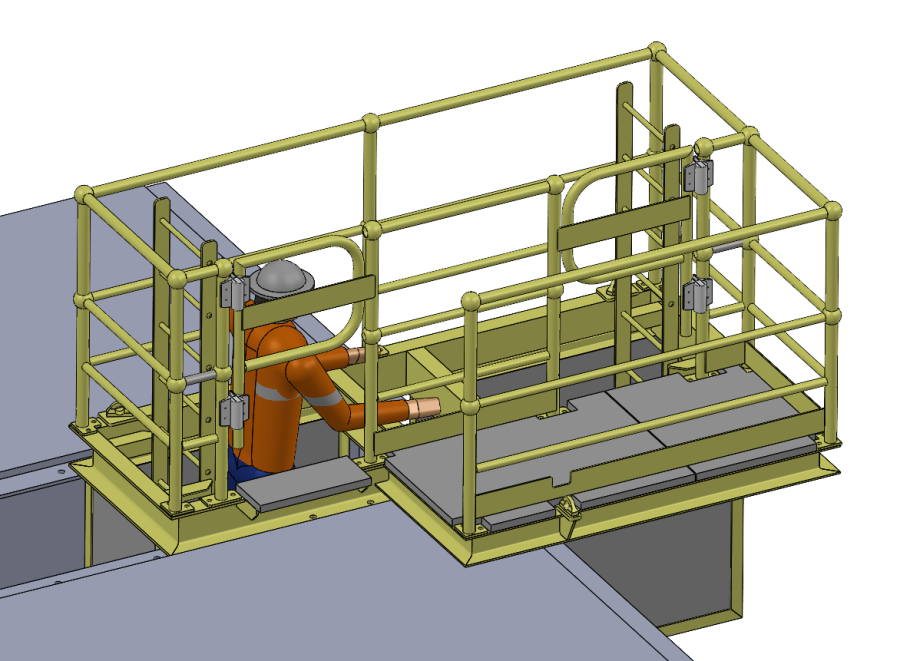

Dynamic Engineering Consultants offers comprehensive solutions for optimizing fabrication efficiency through cutting-edge 3D modeling and drafting services. Our process starts with meticulous measurements or 3D scanning https://www.dynamicengineering.com.au/industrial/2021/10/11/handheld-laser-scanning/ of existing fabrications or creating new designs from scratch. We use state-of-the-art Solidworks TM software to craft 3D models with precision, enabling swift item simulations and adjustments before production. Furthermore, by addressing potential issues early on, we are able to streamline the fabrication process and eliminate the need for later concept reevaluation.

SOLIDWORKS drawings play a vital role in detecting inconsistencies and facilitating modifications during early stages, thereby significantly reducing manufacturing time and enhancing the overall process for cost-effectiveness and meeting tight deadlines. Discover more benefits of Solidworks TM at this web page: https://www.solidworks.com/sites/default/files/2018-06/DS-18021-3D-to%20-3D-Whitepaper.pdf.

The advantages of 3D modeling and drafting include boosted productivity, improved quality, better collaboration, increased innovation whilst also reducing costs.

As the industry transitions to the Internet of Things and Industry 4.0, manufacturers face heightened competitive pressures, demanding higher-quality and more innovative products with greater efficiency and cost-effectiveness. Responding successfully to these challenges necessitates enhanced interconnectivity, data sharing, and automation in product development and manufacturing. Consequently, with over 2000 successfully projects/designs using 3D modeling, Dynamic Engineering Consultants is well-positioned to assist clients. Partner with us to harness the power of 3D modeling and maximize fabrication efficiency today.