Mechanical failure investigations (https://autojusticeattorney.com/mechanical-failure-cause-accidents/) systematically examine the causes of failures, providing a structured process. The field aims to pinpoint the root causes and contributing factors of failures, offering insights to prevent similar occurrences in the future. Engineers understand the behaviour of a system or component leading up to its failure through the seamless integration of engineering principles, materials science, and investigative techniques.

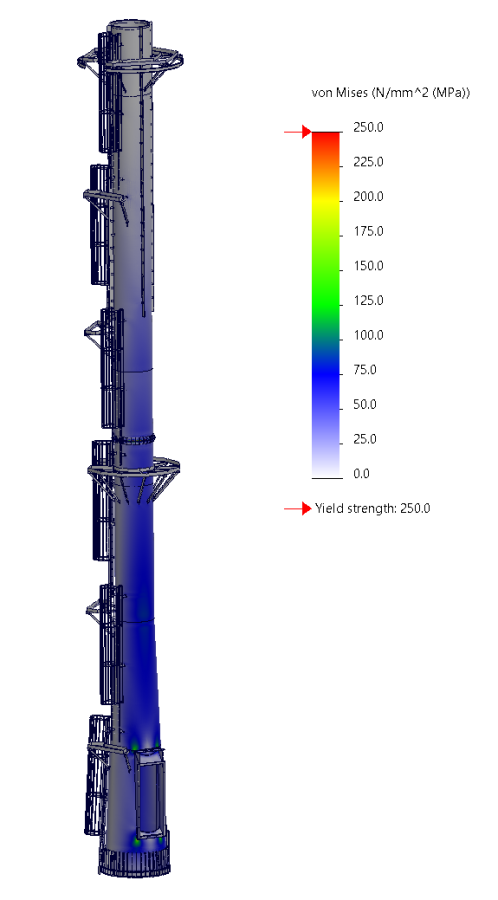

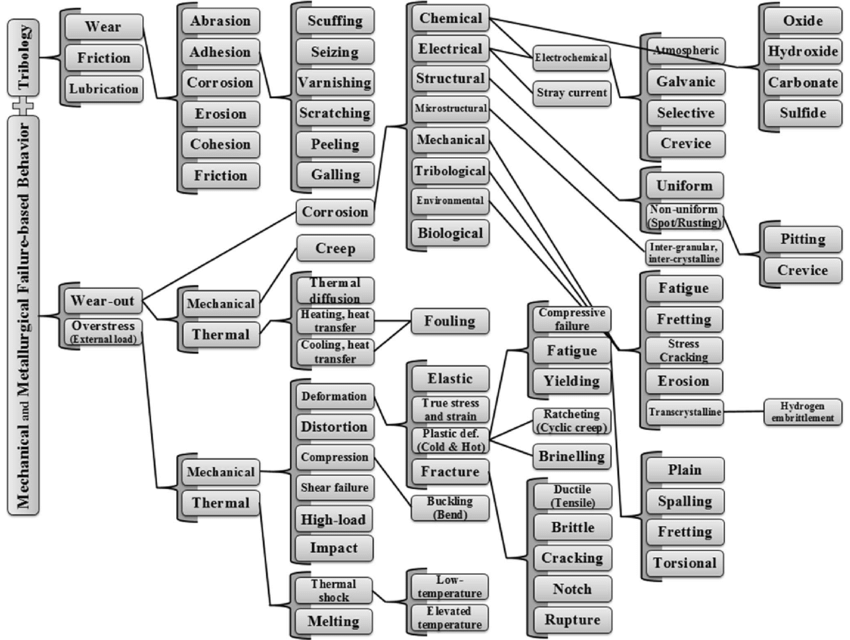

Above image is provided courtesy of the Journal of the Brazilian Society of Mechanical Sciences and Engineering 44(6) June 2022

In mechanical failure investigations, practitioners undertake key steps that encompass documentation, visual inspection, material analysis, non-destructive testing (NDT), mechanical testing, fracture analysis, failure mode and effects analysis (FMEA), simulation and modelling (https://www.dynamicengineering.com.au/industrial/2014/04/18/design-certification/), root cause analysis, and recommendations.

Mechanical failure analysis holds paramount importance across a wide range of industries, including automotive, manufacturing, and mining. Mechanical failure investigations significantly contribute to enhancing the reliability and safety of mechanical systems. This interdisciplinary approach amalgamates knowledge from various fields to effectively address and mitigate the impact of failures.

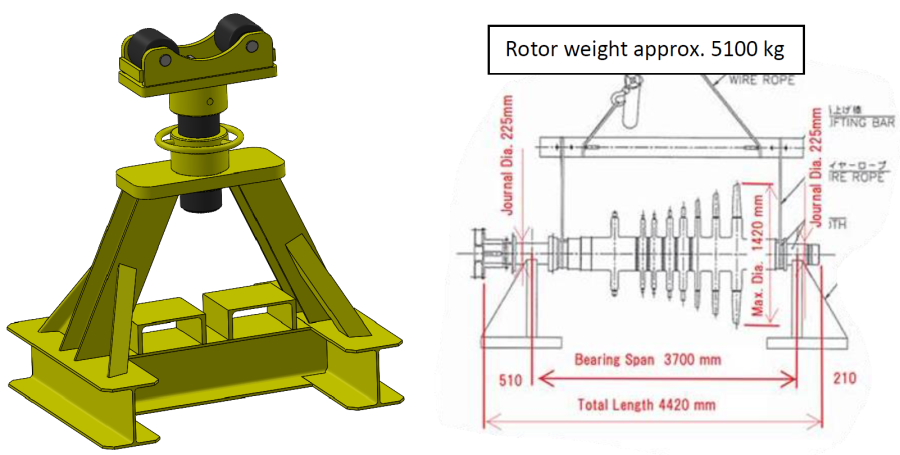

Dynamic Engineering Consultants proudly offers a comprehensive mechanical failure investigation service. The team summarizes the outcome of the investigation in a professional and thorough report. An illustrative example of a transport-related failure investigation is provided below. In this example, a failed dust seal led to lubricant contamination and subsequent bearing failure.

For further inquiries, feel free to give us a call or send us an e-mail via the contact us page.