The remaining life of corroded steel structures hinges on several key factors: the quality of the steel, the fabrication, assembly, and construction processes, the environmental conditions it faces, and the maintenance it receives over time. When a steel structure was designed, fabricated and maintained properly, it can endure for decades or even centuries.

The primary factors influencing a steel structure’s lifespan:

- Quality and Grade of Steel: The durability of structural steel relies heavily on its quality and grade. High-quality steel produced under strict industry standards, with higher carbon content and proper alloying elements, offers enhanced strength and corrosion resistance, ensuring a longer service life. Also refer to the resources provided by the Australian Steel Institute that can be found here

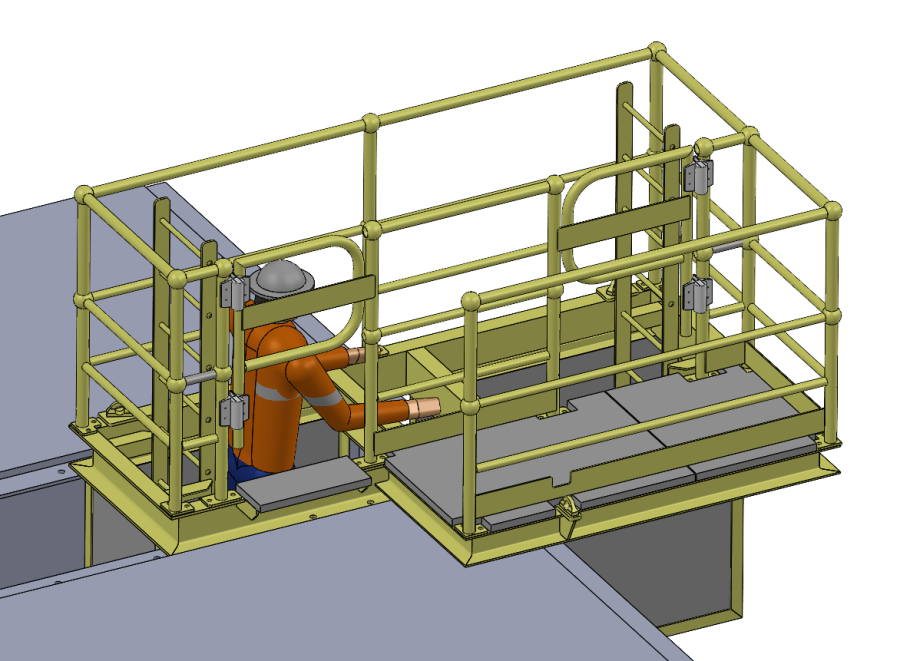

- Design and Construction Quality: The quality of the design, detailing, and construction significantly affects structural steel’s longevity. A well-designed and accurately fabricated structure can better resist fatigue, deformation, and other stresses that threaten its lifespan.

- Corrosion Protection: Corrosion poses a major challenge to the longevity of structural steel. Implementing proper protection methods, such as galvanizing or applying protective coatings, can greatly extend the lifespan by preventing rust and corrosion in harsh environments.

- Regular Maintenance and Inspection: Conducting regular maintenance and inspections is crucial for preserving the structural integrity of steel. Periodic checks for signs of corrosion, fatigue, or damage, followed by timely repairs or treatments, help prevent minor issues from escalating into significant problems.

- Environmental Factors: The installation environment impacts the longevity of structural steel. Excessive moisture, saltwater, chemicals, or extreme temperatures can accelerate deterioration. In corrosive settings, applying appropriate coatings and maintenance becomes even more vital.

- Load-Bearing Capacity: Structural steel is designed to handle specific stresses and loads. Overloading or subjecting it to forces beyond its design capacity can cause premature wear and shorten its lifespan.

When corrosion damage occurs, you may wonder: “Is the corroded structure still safe, and what level of corrosion would render it unsafe?” Dynamic Engineering Consultants can help answer this.

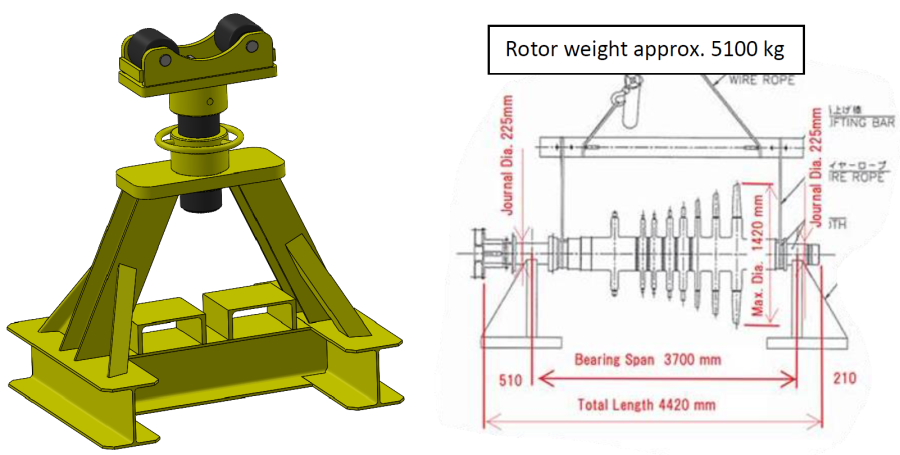

The analysis process used to determine the remaining life of corroded structures involves:

- Obtaining drawings or measuring the structure

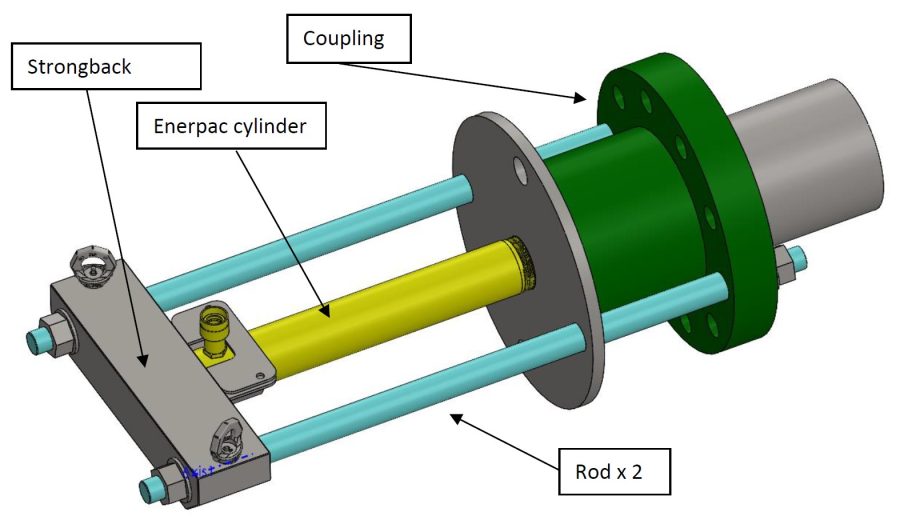

- Measuring remaining material thickness using NDT techniques

- Determining design loads (e.g., wind loads, live loads)

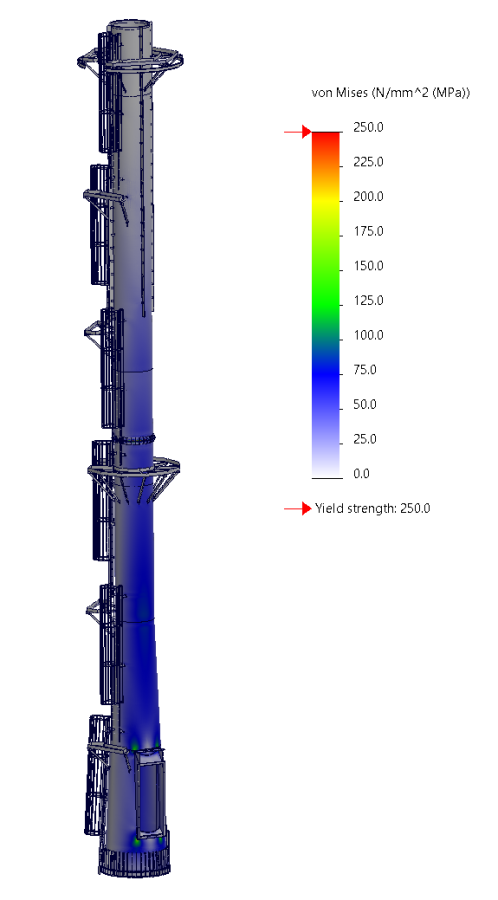

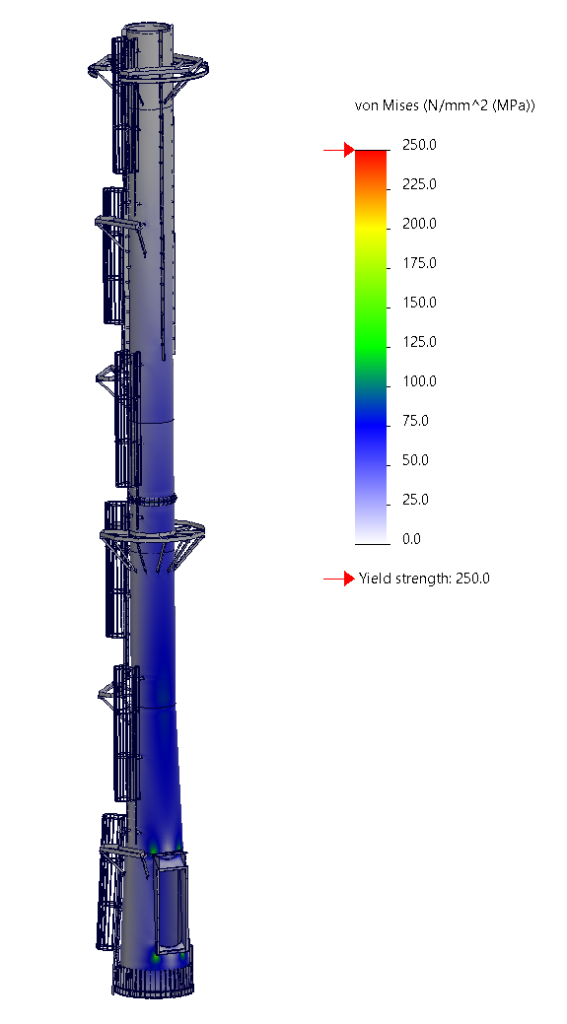

- Generating a 3D model of the corroded structure

- Analysing the structure’s performance in response to applied loads in accordance with relevant Australian standards

- Identifying when and what repair actions are necessary

For instance, we analysed a stack using this method.

Dynamic Engineering Consultants can assist with estimating the remaining life of corroded structures. If you have a similar project to discuss, send us an email or give us a call today using the details on our contact page.